Abstract

The global manufacturing area has changed significantly over the past couple of decades, and Australian manufacturing is not an exception. Advanced technologies (High Tech) have the potential to benefit all manufacturers across Australia. This includes a number of digital technologies that are often part of the digital transformation projects for businesses (also known as Industry 4.0).

Example of these advanced digital technologies is robotics, 3D printing, artificial intelligence, Machine Learning, nanotechnology, biotechnology as well as automation.

Among these technologies, there is one that is not new. It has been there for more than a decade and has been adopted by many manufacturers around the world.

Automation!

This article illustrates why and how the business needs a robust system to boost up overall manufacturing processes. This article talks about the everyday challenges of manufacturers and how an ERP system can address these challenges. This article's primary audience is the managers and heads of departments at small or mid-sized manufacturing businesses in Australia who are looking for efficient solutions for Production management, Inventory management, Sales and purchase management, and accounting and finance management.

This blog article concludes with a brief note on some of the benefits of using the ERP system in the manufacturing business to maximize returns on investment.

Introduction

The manufacturing industry has one of the fastest-paced environments where every second is countable and may lead a business towards success or failure. However, it comes as a big surprise that many manufacturers, particularly the small and midsized manufacturers in Australia, are still unsure about the move. Despite facing many numbers of challenges in their daily operational activities, they still fear any changes to adopt digital technologies. It is not about the absolute absence of technology. Some manufacturers still using different software for different departments. However, the processes are still not centralized. Such a quick method of using technology (like using Excel spreadsheets here and there !) might let manufacturers operate with business functions associated with each and every team, but managing functions with a disjoint system is prone to inaccuracy inconsistency. It's time for getting an overview of an entire business. Put aside all new technologies like AI machine learning, and let's talk about a type of computer system that has been there for more than a decade and has proven to improve efficiencies of even the top manufacturing businesses around the world like Boeing! A robust solution that enables real-time tracking, audit, mobile access to the system, and forecasting intelligence for the company called Enterprise Resource Planning (ERP) and thanks to the advancement of software engineering, It doesn't cost the Australian manufacturing industry a fortune to get the latest ERP tech setup to get all the benefits that the top manufacturers.

Top 9 Crucial Business Functions which Affect Most to the Manufacturing Performances:

1. Inventory controlling

2. Purchase Management

3. Material Management

4. Operation and Production Management

5. Quality Assurance

6. Sales

7. Customer Relationship Management

8. Accounting and Invoicing

9. Human Resource

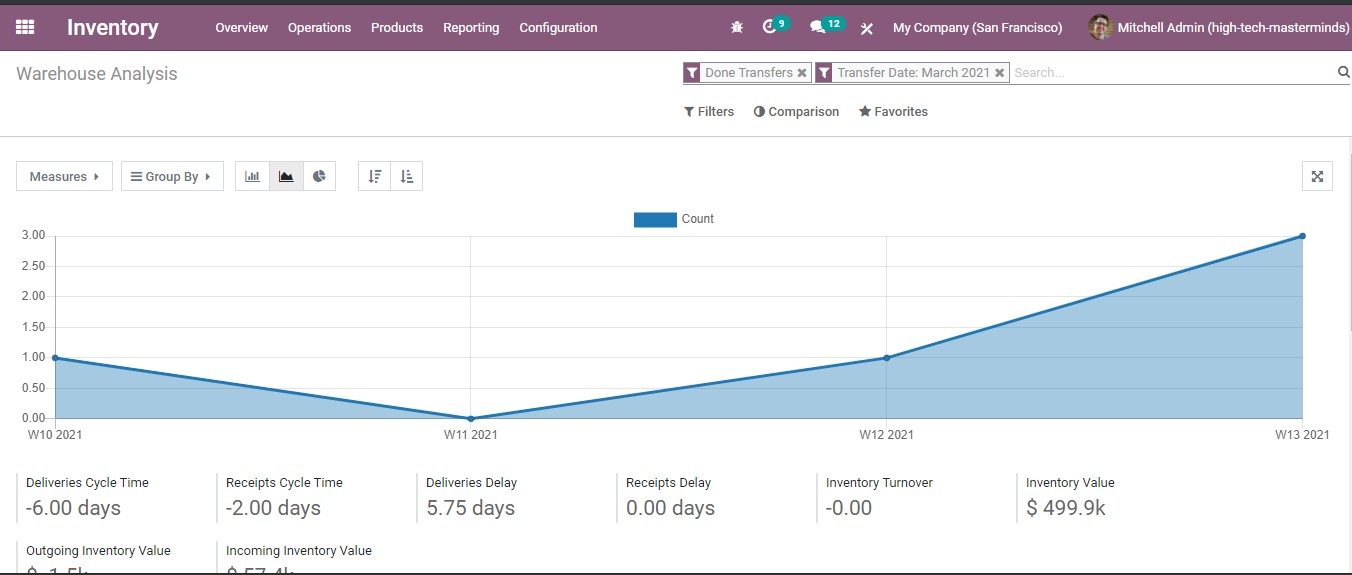

Inventory Controlling Challenges for Small to mid-sized manufacturers:

How ERP Systems like Odoo address the Inventory Controlling challenges:

Purchase Management challenges for Small to mid-sized manufacturers:

How ERP Systems like Odoo address the purchase management challenges:

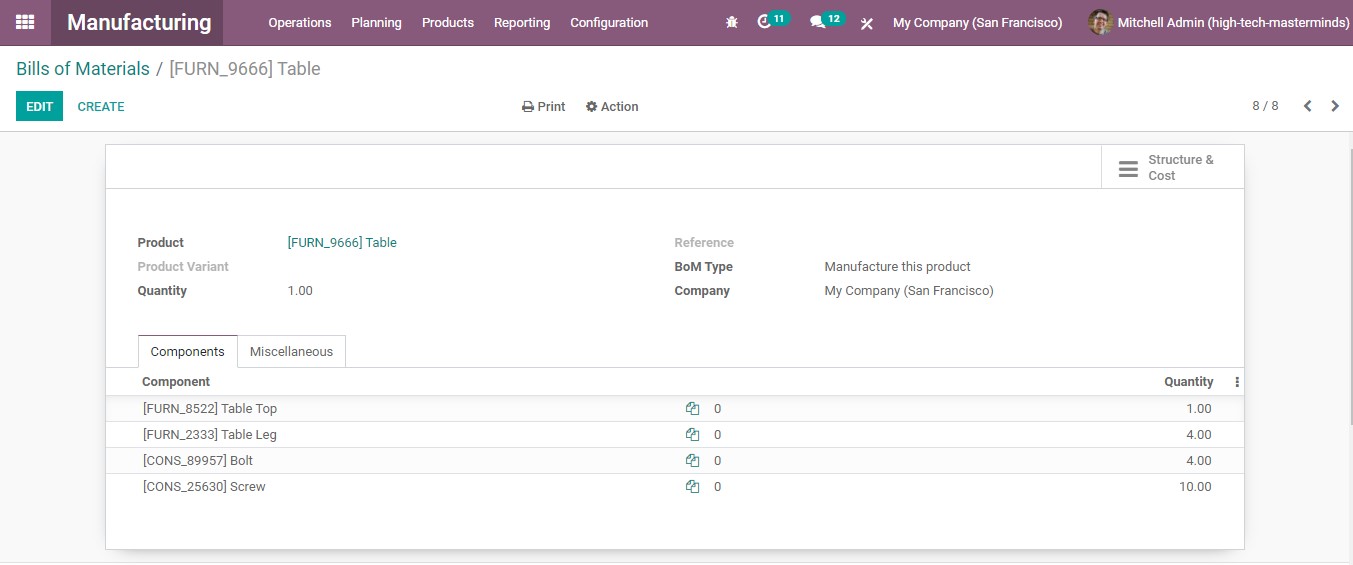

Material Management Challenges for Small to mid-sized manufacturers:

How ERP Systems Address Material Management Challenges::

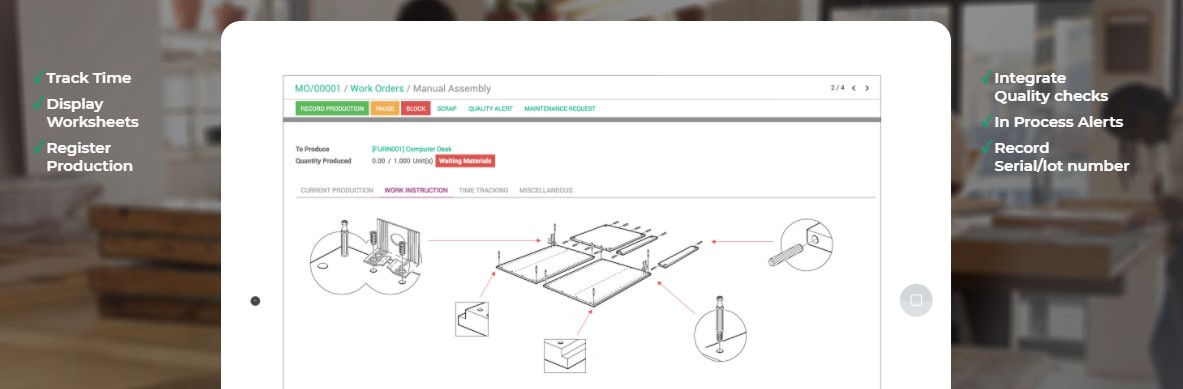

Operation and Production Management Challenges for Small to mid-sized manufacturers:

How ERP Systems Address Operation and Production Management Challenges:

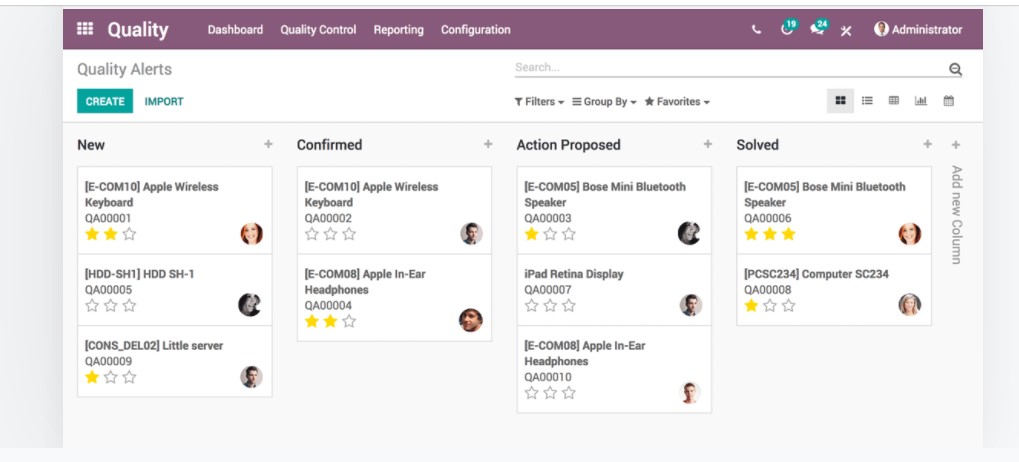

Quality Assurance Challenges for Small to mid-sized manufacturers:

How ERP Systems Address Quality Assurance Challenges:

A robust ERP allows its user to set different values as the parameters for testing the products during production.

The manufacturer can create a list of accepted, rejected products for further actions.

Sales Challenges for Small to mid-sized manufacturers:

How ERP Systems Address Sales Challenges:

Customer Relationship Management Challenges for Small to mid-sized manufacturers:

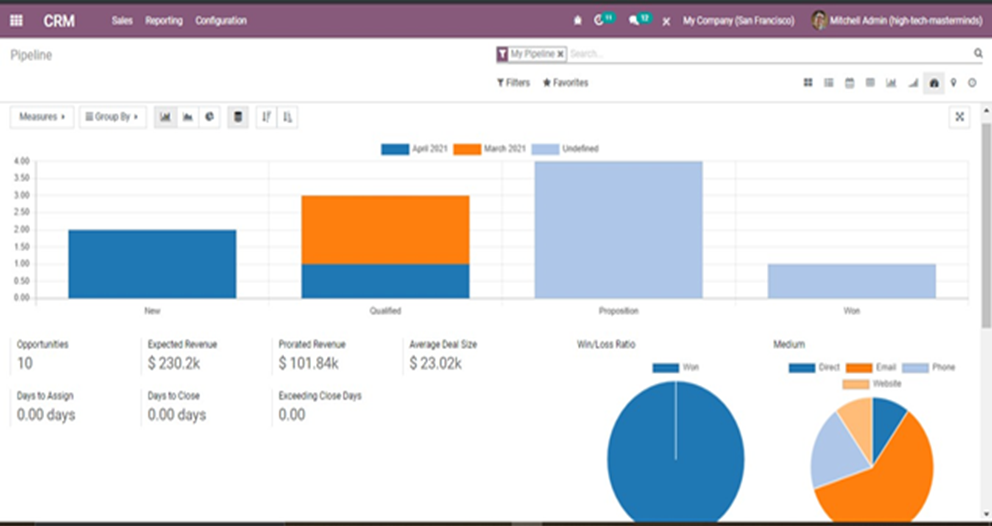

How ERP Systems Address Customer Relationship Management Challenges:

It enables the feature for scheduling any activities such as calls, meetings, mailing, and quotations based on sales scripts. CRM department can get all the information from the website viewed mail received list.

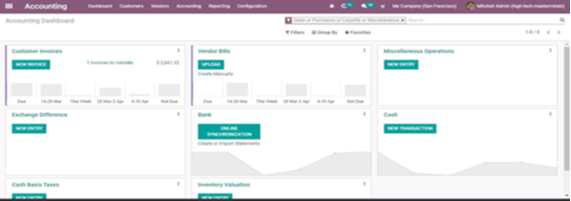

Accounting and Invoicing Challenges for Small to mid-sized manufacturers:

Cybersecurity is another concern in different platforms for accounting tasks since there is a lack of security integration.

How ERP Systems Address Accounting and Invoicecing Challenges:

Human Resource Challenges for Small to mid-sized manufacturers:

How ERP Systems Address Human Resources Challenges:

Conclusion:

References:

About us:

Ahad Mahmud, Business Analyst

Ahad is an IT- Business Analyst at High Tech Masterminds. He strives to create informative, well-researched, digital content. He is often designing and developing course contents and materials to assist customers in Odoo ERP implementation. He has 3+ years of experience in evaluating stories, shaping content, and accelerating overall work quality in electronic media.

Want an ERP Solution to boost up your manufacturing performance?

50,000+ companies run Odoo to grow their businesses.

Book a free 1h Consulting session with us.

Common challenges for Small to mid-sized manufacturers to adopt advanced manufacturing technologies